Production

Başlık Ekle

Metni değiştirip kendi metninizi eklemek için buraya tıklayın.

Design

Genhidsan Hydraulic Cylinder Design Department is dedicated to turning customer requirements into reliable and high-performance solutions. We are not only a manufacturing partner but also an engineering partner, working with our clients from the earliest design phase to ensure every cylinder is optimized for performance, durability, and cost efficiency.

Our team of experienced design engineers develops hydraulic cylinders based on each application’s technical specifications. Whether it is creating a brand-new design from scratch or reviewing existing drawings, we provide detailed feedback from a manufacturability perspective and guide our customers toward the most effective solutions.

With advanced computer-aided design tools (Autodesk Inventor) and strong know-how in materials, sealing systems, and machining processes, our department ensures that every hydraulic cylinder meets international quality standards and performs flawlessly in demanding environments.

Machining

At Genhidsan, we recognize that true product quality is the result of the right combination of advanced equipment, precise measurement, and highly skilled personnel.

Our Machining Department is equipped with state-of-the-art CNC machines and reinforced by regularly calibrated measuring instruments to guarantee dimensional accuracy at every stage of production. Supported by a technical team whose expertise is constantly enhanced through continuous training, we ensure that each component is manufactured with maximum precision, safety, and reliability.

By combining modern machining technologies with strict process control, our department delivers components that not only meet but exceed international quality standards, forming the foundation for robust and long-lasting hydraulic cylinders.

Başlık Ekle

Metni değiştirip kendi metninizi eklemek için buraya tıklayın.

Başlık Ekle

Metni değiştirip kendi metninizi eklemek için buraya tıklayın.

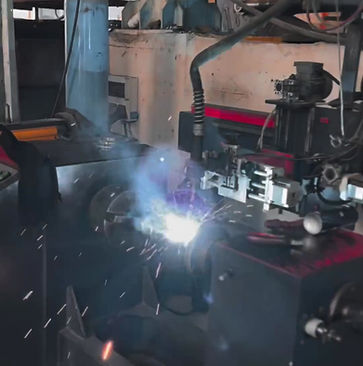

Welding

Our Welding Department is certified according to EN ISO 3834-2 and equipped with modern MIG, MAG, and TIG welding systems. With the support of advanced welding positioners, we ensure high-quality welded manufacturing with maximum precision, consistency, and efficiency.

Our welding personnel are certified in accordance with EN ISO 9606-1 and EN ISO 14732 standards, and their qualifications are renewed every six months under the supervision of our in-house International Welding Engineer (IWE). This continuous requalification process ensures that our team’s expertise and technical skills remain at the highest level.

By combining modern infrastructure with a highly competent technical team, our Welding Department provides the foundation for manufacturing safe, robust, and reliable hydraulic cylinders.

Assembly & Testing

At Genhidsan, the assembly infrastructure is primarily designed to ensure the safe and long-term use of hydraulic cylinders. Before assembly, all parts are thoroughly washed in industrial cleaning machines, and every assembly area is carefully prepared. Depending on cylinder forms, the process is supported by both horizontal and vertical positioned assembly equipment, ensuring precision and efficiency.

Every hydraulic cylinder manufactured by Genhidsan undergoes 100% testing and is certified according to EN 10204 – 2.2 standards. All tests are performed under strict procedures, simulating real operating conditions to guarantee durability, reliability, and safety.

The testing process includes:

-

Working pressure verification

-

Functional controls

-

Cushion control and adjustments

-

Safety valve and operating speed control (if applicable)

-

Dimensional checks

-

Durability tests under high pressure (working pressure × 1.5)

-

No-load running tests at low pressure

-

Internal and external leakage detection

Through this systematic approach, our Assembly & Testing Department ensures that every cylinder leaving our facility is safe, durable, and fully reliable in the field.

Başlık Ekle

Metni değiştirip kendi metninizi eklemek için buraya tıklayın.

Başlık Ekle

Metni değiştirip kendi metninizi eklemek için buraya tıklayın.

Coating & Paiting

At Genhidsan, surface protection is approached as a critical stage in ensuring the durability and performance of hydraulic cylinders. Our Painting Department applies the wet-on-wet procedure, which provides superior adhesion and consistent coating quality.

The standard process includes:

Surface preparation and cleaning before painting

Application of epoxy primer (~60 – ~80 µm)

Application of acrylic topcoat (~40 – ~60 µm)

All processes are performed under controlled conditions in accordance with international standards such as ASTM B117 and ISO 9227, ensuring reliable and repeatable results.

In addition to standard painting, we also offer alternative surface treatment methods tailored to customer and industry requirements, including:

Phosphate coating

Cadmium plating

Galvanized coating

Nitridation & carburization

Solid film lubrication

By combining advanced coating technologies with strict process control, our Painting & Surface Treatment Department guarantees that every cylinder is protected against corrosion, wear, and demanding operating environments.